Ernest B. Wysong

Ernest B. WysongHave you ever wondered how your favorite frozen foods can survive the weeks-long trek to your local stores? As much as we all love a home-cooked meal, sometimes the allure of your favorite frozen pizza, veggies or microwave meal is too much to pass up, and we indulge ourselves. Modern cold-chain technology allows those items to make it from their point of origin to the consumer efficiently and safely. Most consumers are aware of the simple journey of food and medicine from grocery stores and pharmacies to their homes, but what they may not be aware of is the more complex voyage these products make all along the cold chain.

A cold chain is a temperature-controlled supply chain that helps ensure and extend the shelf life of products in the food and pharmaceutical industries. Cold-chain goods are perishable and must be kept within specific temperatures while en route to their destinations. Because some journeys are longer than others and the products being transported can be sensitive to temperature changes, it is essential that cold-chain containers keep products at the right temperatures effectively and efficiently. A key to accomplishing this is the use of polyurethane foam for insulation in cold-chain shipping containers.

From production to a commercial fridge or freezer, rigid polyurethane foam insulation is one of the most frequently used materials in the cold chain because it’s energy efficient, durable and lightweight. Because of these advantages, rigid polyurethane foam is invaluable to the cold supply chain.

Energy Saving Potential with Polyurethane Rigid Foam

On average, the journey of a complete pallet of frozen foods takes 75 days from the warehouse to the household freezer.[1] A tub of ice cream starts in a warehouse, travels in a truck and lands on a shelf in the supermarket before finding its way to someone’s home — all within different freezers. Traveling long distances in different climates and weather conditions makes the insulation of different storage units in the supply chain a critical aspect to keeping food and pharmaceuticals cooled to the right temperature. It is essential that trucks are able to maintain the proper temperature over long distances to deliver these products, especially for populations that live in secluded areas or food deserts — geographic areas where there is limited access to affordable or good-quality fresh food.

Fundamentally speaking, the better the insulation, the more energy can be saved. The combination of a lightweight and closed-cell structure with encapsulated insulating gas is a primary advantage of insulating with polyurethane foam. Its insulation performance is extremely high even with a modest material thickness.[2] Insulation made from polyurethane not only contributes to the strength of the container carrying the cargo, but it also prolongs the life of the product by allowing longer travel times from production to storefront or pharmacy. The light weight of the insulation allows for fuel savings as well.

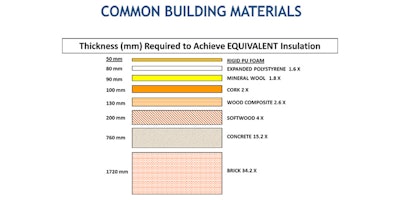

By effectively minimizing air leaks in transportation trucks and refrigerators, the cold air stays in the space, and less energy is needed to keep these spaces cool. Polyurethane foam insulation also has a high R-value, which is the resistance to heat flow given a certain thickness of material. A recent industry analysis showed storage units throughout the cold chain that used rigid polyurethane foam with optimized insulating thickness were able to save 16 times more energy than what went into the production of the insulating material.[3] Polyurethane rigid foam can save resources and provide 50-75 percent more efficient performance on an equal thickness basis versus other types of common insulation material that may suffice. Therefore, it’s not surprising that polyurethane can be found in many parts of a cold supply chain. In some systems, it can be found in every element.[4]

Eco-Efficiency and Sustainability

The eco-efficiency rewards from rigid polyurethane foam are a result of its extraordinary ability to keep heat out and cool air, a situation not only found in trucks and shipping equipment. Polyurethane foam insulation is also found in other parts of the cold chain, including commercial and household appliances. Analysis shows a modern appliance with polyurethane insulation has an energy-savings factor of 20:1. Such an appliance becomes a figurative “piggy bank,” within a mere seven days — the duration the specific cold chain examined for the study — the freezer saved 20 times more energy than what is required for the production of the polyurethane. Extrapolated over an entire year, this would rise to a factor of roughly 1,040:1.[5]

Increasing energy-saving potential with the use of polyurethanes provides benefits to our environment. According to an industry study, more than 40 percent of energy used to heat and cool the inside of buildings and homes, including structures like walk-in freezers, comes from fossil fuels.[6] The use of polyurethane insulation in these buildings increases energy savings and, therefore, can help lower carbon dioxide emissions from energy generation. Vehicle manufacturers are playing an important role in the decrease of carbon dioxide emissions as well by using polyurethane foams to create lighter vehicles and reduce fuel consumption.[7] The vehicles that function as a mode of transportation in the cold chain not only require rigid polyurethane insulation to maintain the appropriate temperature for the products, they also benefit from it being a more efficient means to get from point A to point B while leaving behind a smaller environmental footprint.

The polyurethane industry is supporting innovative manufacturing technologies that will help reduce the global warming potential (GWP) of its final products. Newer foaming and blowing agents are making foams even more energy efficient and offer a lower GWP footprint. The implementation of lower GWP agents has increased the environmental benefits of using polyurethane foams in cold-chain systems. With new manufacturing methods and superior foaming and blowing agents, polyurethane foam has increased its superior insulation qualities while also addressing global climate issues.[8]

The industry employs cutting-edge measures to improve sustainability in the manufacturing, installation and distribution of polyurethane foam in cold chains. These measures create greater efficiency during transportation while minimizing the waste of products shipped, thus increasing the quality and quantity of yields.[9] With modern polyurethane insulation optimizing energy saving capabilities and reducing carbon dioxide emissions, it’s helping companies and individuals meet their sustainability and environmental goals. Polyurethane insulation is keeping pace with a continuously evolving industry and economic demands.

By Ernest B. Wysong, Ph.D., the global technology leader for the Opteon Foam Applications at Chemours Fluoroproducts.

[1].https://www.plasticsportal.net/wa/plasticsEU~pl_PL/portal/show/common/plasticsportal_news/2010/10_312?doc_lang=en_GB

[2] http://www.react-ite.eu/uploads/tx_mddownloadbox/PP02_Thermal_insulation_materials_-_PP02_20130715.pdf

[3].https://www.plasticsportal.net/wa/plasticsEU~pl_PL/portal/show/common/plasticsportal_news/2010/10_312?doc_lang=en_GB

[4] http://polyurethanes.org/uploads/documents/foodcold.pdf

[5].https://www.plasticsportal.net/wa/plasticsEU~pl_PL/portal/show/common/plasticsportal_news/2010/10_312?doc_lang=en_GB

[6] https://docplayer.net/30361731-Polyurethanes-are-polymers-made-by-reacting-diisocyanates-mdi-and-or-tdi-with-a-range-of-polyols-the-density-of-the-product-is-determined-by-the.html

[7] http://polyurethanes.org/en/sustainability/sustainable-development/environmental-responsibility

[8].https://www.dow.com/en-us/search.html

[9] https://www.dow.com/en-us/polyurethanes/markets-and-applications/insulationscience/professional-cold-chain-and-commercial-appliance