In early March of this year, independent research firm CE Delft released some eye-opening stats on cultivated (animal-free) meat, stating that cultivated meat made directly from cells, in comparison with conventional meat, may cause up to 92% less global warming impacts, have 93% less air pollution and use up to 95% less land and 78% less water. Further, the firm's research models indicated that, through the use of large-scale production facilities, cultivated meat could become cost-competitive with animal meat by 2030, with its cost dropping to $2.57 per pound by then.

So, with its environmental advantages and favorable pricing outlook, is cultivated the way of the future? To dive into this topic, we recently spoke with Eric Jenkusky, the co-founder and CEO of Matrix Meats, a technology provider that utilizes nano-fiber scaffold design to produce cultivated meat in Columbus, OH. Matrix's scaffold technology replicates the extra cellular matrix of living organisms, enabling customizable meat production.

We asked Jenkusky all about what goes into cultivated meat production and its outlook.

Food Manufacturing: Cultivated meat has had an uptick in popularity recently, what is cultivated meat and how does Matrix Meats fit into it?

Jenkusky

Jenkusky

Matrix Meats aids in the creation of an animal-free scaffold with our custom-engineered 3D nanofibers on which cultivated meat can be grown. The scaffolding mimics the extra cellular matrix found within every living organism and helps cells multiply and mature into textured fibers more easily. The scaffolding can be customized to adjust shape, thickness, and texture. We work with manufacturers to grow a product that’s completely customizable to their needs, whether that’s replicating a chicken nugget, hamburger, or T-bone steak. Vitamins, minerals, proteins and other ingredients requested by the manufacturer can also be embedded into the scaffold.

FM: What are the advantages of cultivated meat opposed to real meat and how will this affect the food industry as a whole?

Jenkusky: It is projected, that by 2050, there will be a need to feed almost 10 billion people worldwide and it’s no secret that the food industry is recognizing the way we approach meat manufacturing is inefficient and unsustainable. Raising livestock for slaughter is extremely time-consuming and requires a lot of land and water, accelerates climate change, and adds to pollution.

Cultivated meat can solve this. According to a recent study from CE Delft, cultivated meat results in 92% less global warming, 93% less air pollution, and uses up to 95% less land and 78% less water than conventional meat production.

We won’t have the resources to feed our communities in the years to come if the food industry does not adapt. Furthermore, countries that don’t have fit environments to raise livestock will simply need a facility to grow their own meat. Cultivated meat is the sustainable solution.

FM: What makes the cultivated meat space stand out in the overall alternative proteins sector?

Jenkusky: There are more than 80 companies currently in the cultivated meat space and we are working with about a quarter of them to get their products to market. The industry is collectively working on a common solution to a global problem. Our work is fueled by doing better for the world and our future communities of people. By eliminating the need to destroy rainforests in order to create pastures for livestock, along with eliminating animal slaughter, we’re providing the world with regular access to clean, healthy food. What other food space can say they’re feeding the future sustainably and evolving the food industry as a whole?

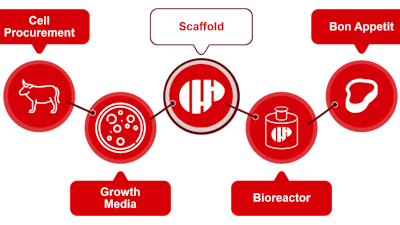

FM: Describe the full process to which you aid in creating cultivated meat.

Jenskusky: At Matrix, we can take a variety of synthetic and natural materials to create custom, proprietary blends that fit our customers’ specific needs. We create these blends, through a process called electrospinning, to form materials into a fibrous scaffold for cell cultures. We can fine tune and optimize a number of these processes for our customers.

We can also customize properties of the scaffold such as alignment, fiber size, etc. to influence and improve cell growth. We can also customize the form factor of the scaffold material in large 3D sheets that can be shipped in rolls or in a micro carrier form.

In the cultivated meat space, adherent cells need something to attach to so that they can multiply. Without the use of a scaffold product, the cells struggle to grow. The proliferation/yield is hampered dramatically. The use of a scaffold material for cultivated meat is critical because it not only increases the process throughput (more cells), but also because scaffolds allow for manipulation and fine tuning of the cell as they mature into various structures.

The proliferation rate is directly correlated to how much meat the meat producer can create per year. The more efficient the process, the lower the cost. So, we aid in volume and cost-efficacy.

With regards to the 3D scaffold product, we can control the alignment of the fibers. This, in turn, can guide the muscle cells and encourage their formation into the larger muscle bundles that you expect in meat, therefore bringing the product closer in texture and mouthfeel to the “real” thing. Likewise, we can cater the meat to the customers’ needs such as marbling, thickness, and what vitamins are infused.

FM: What’s the future of the cultivated meat industry and is this the future of the meat industry?

Jenkusky: There is a lot of excitement, but the staying power of cultivated meat is the fact that we will never phase out traditional farming completely. If we can phase out the proportions, that a farm raised cow is a luxury item, that is the way to go. We think traditional fishing, cattle ranching, etc. will always be around, and that’s totally okay. If cultured meat can supplement that, we will make huge strides in our ecological efforts. Also, unlike plant-based alternatives, we are working towards the real thing. If we do our jobs well, it will be indistinguishable, not because we faked it, but because it is the same thing. This will also avoid the use of GMOs, organic, antibiotics, hormones, etc.