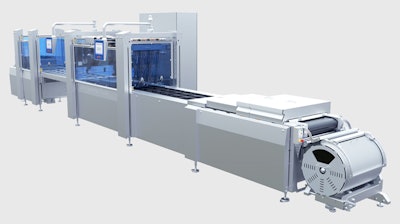

GEA PowerPak PLUS is the newest thermoforming packaging system from GEA featuring full visibility at the sealing station during production, automatic top and bottom film alignment for perfect sealing and change-over and set-up times that take just minutes. PowerPak PLUS is designed around efficiency, promoting excellent package quality, reduced film consumption, fast and simple handling, more uptime and low total cost of ownership.

The new standard in thermoforming

Based on our in-depth understanding of customers’ needs and more than 60 years of technology expertise in thermoforming, the new PowerPak PLUS series is packed with innovations, all driving towards a common goal: making your products better and your work easier and more efficient.

Main applications

GEA PowerPak PLUS embraces an abundance of packaging types. A single machine for air, vacuum, MAP, steam, skin, topforming and shrink packaging with various easy opening and reclosability features. The main variety of food products include meat, processed meat, poultry, fish & seafood, dairy, bakery, convenience foods, fruits & vegetables. The GEA PowerPak PLUS can also pack medical and technical goods.

Performance

- Motor-driven film unwinding systems in combination with web tensioning systems provide controlled film unwinding to improve sealing seam quality

- Automatic monitoring and regulating of the axial position of the bottom and top webs

- Motorized and controllable web tensioning systems for optimal film tension, extremely low and even forces on the top and bottom web

- Outstanding GEA valve technology for monitored evacuation and gassing processes

Reliability

- Over 98% uptime, monitored and proven in the field

- Massive and robust frame concept. GEA membrane sealing system ensures tight and even seals

- Strongest film transport chain with servo drives keeps the film in optimal position

- Maintenance-free lifting systems for forming and sealing

Flexibility

- GEA PowerChange enables quick, efficient and fast die set configuration changes

- Divided deep draw lid for quick die set change-overs. Automatic film thickness compensation

- Automatic film replacement positions shorten replacement times and reduce film consumption

- Vertically moveable safety doors for easy and quick access and interventions