High-mix food manufacturing and food production has been historically difficult to automate.

Given they have high mix — i.e., many SKUs — these production teams will change over a line from one product to another, such as a 3,000-tray run of jambalaya rice and then an 8,000-tray run of bean stew mix on the same line. A manufacturer may do changeovers like this up to 20 times per day.

Manufacturers have tried unsuccessfully using traditional automation including multi-head dispensers, vertical form fillers, weigh scales, vibratory feeds and augers. Because of the variability of each ingredient – for example, sticky rice behaves differently than a sauce – along with the large amount of time needed to clean a depositor between runs, manufacturers end up having to use people. People, of course, can very quickly changeover and are flexible to the SKU properties, different portion sizes, placement quadrants and tray.

Unfortunately, given the scale of most food manufacturers and the fact that most operations are two shifts, these factories require quite a bit of labor to sustain demand. However, because of: 1) the repetitive motions necessary to do production / assembly, and 2) the fact that most of these environments are cold room environments (~33°F), hiring and retaining labor is an ongoing challenge. This results in manufacturers running severely under-capacity, often their no. 1 pain point.

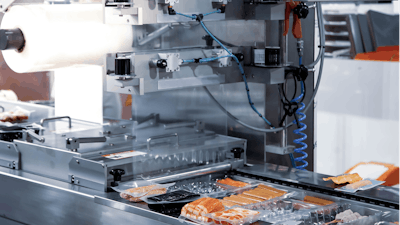

To solve this problem, Chef Robotics has released an AI-enabled Robotic Solution. Unlike traditional depositors, Chef mimics the flexibility of human pick-and-place motions. Chef Systems use AI to sense where in a pan of food to pick from and where the containers are. This AI, alongside interchangeable utensils, allows Chef to be as flexible as a human: Chef can pick the vast majority of “scoopable” ingredients a human can, be as consistent as a person, work with any portion size, place components anywhere on the tray in a precise manner, work with almost all trays, and work with almost all conveyors. In doing so, Chef provides a system that is a human equivalent.

Further, Chef Systems don’t require any retrofitting of a line: Chef Systems take the same footprint as a person, are on casters (i.e., not bolted to the ground) and moveable, and only require two inputs, 110V power line and a standard compressed air line. Thus, they can easily slide onto an existing line without having to fully automate the line.

To date, Chef has done over 1,720,000 servings in production through partnerships with a large frozen food manufacturer, a contract manufacturer, and a direct-to-consumer meal provider.

Customers have seen that:

- They can overcome the labor shortage, increase production volume, and scale more easily while maintaining a lean workforce.

- They can improve yield through less giveaway and increased product consistency

- They can reduce the risk of worker injuries through redundant strain injuries.

- Since Chef tracks the weight of every deposit, they have data and visibility into what's happening on their production lines from anywhere in the world.

The existing labor force views the Chef Systems as helpful aids that handle the toughest tasks and help improve the efficiency of the production lines. Now, instead of performing repetitive motions, the workers are trained as robot operators, responsible for selecting the upcoming meals the robots will assemble. This shift reduces the need for redundant motions and allows them to focus their time on ensuring smoother production runs.

In 2023, Chef is looking to more than double its number of robots in production and will be expanding its deployments internationally.