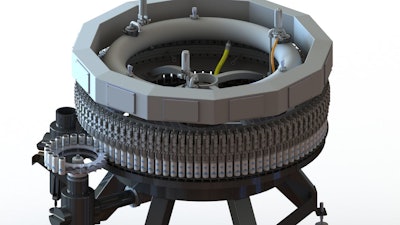

JBT Corporation’s Bevcorp, a beverage filling technology company, announces the launch of its latest innovation, the REVolution EV Filler. This state-of-the-art rotary EV filler represents a significant advancement in beverage filling technology.

The REVolution EV Filler marks a new era in JBT Bevcorp's product offerings, incorporating a new-concept, pressurized product distribution manifold with a simplified, sectioned design. This innovative design allows JBT Bevcorp to streamline the manufacturing process, eliminating the need to rebuild or salvage tanks from legacy equipment. The REVolution EV Filler features an updated method for opening and shutting valves, with the entire filling cycle controlled and monitored by computer. This results in lowered energy use, more accurate fills, reduced foaming and increased yields, enhancing both product quality and production efficiency.

A standout feature of the REVolution EV Filler is the REV Drop-in-Drive, a patent-pending sub-system that allows the servo drive and starwheel assembly to be lifted from its column as a single assembly by loosening only a few bolts. This modular design allows for easier maintenance and quicker repairs. Additionally, REV ID, another patent-pending JBT Bevcorp innovation, plays a crucial role in monitoring, predicting and managing the life expectancy of machine parts. When the machine is stopped, the system writes to the embedded RFID tags, providing detailed information on the remaining life expectancy and the number of cans processed, ensuring precise tracking of the part's lifecycle. This data can be accessed at the part level, and customers are notified of the remaining life of each part.

The REVolution EV Filler features the REV Hygienic Base, a design that harmonizes components across JBT Bevcorp's filler frames. This supports the stocking of pre-manufactured bases and promotes shorter delivery times. The REV Hygienic Base also incorporates the patent-pending REV Drop-in Drive System which in addition to its functional advantages, has a patent-pending distance adjustment that speeds installation and changeover. Additionally, this new base design eliminates unhygienic horizontal surfaces below the product line and distributes weight and forces more evenly, reducing the overall machine weight.

Moreover, the REVolution EV Filler boasts an advanced traceability system (REV ID) for critical components, including the dispensing nozzle that are capable of being individually addressed and tracked. When paired with an appropriate coding system, individual products can be coded to include information allowing an individual container to be tracked all the way back to the valve that filled it, along with the standard batching information that is typically traced. This is particularly valuable for applications in the nutraceutical space, where product traceability is critical. JBT Bevcorp's REVolution EV Filler is set to redefine beverage-filling technology standards, offering advantages in precision, efficiency and versatility.