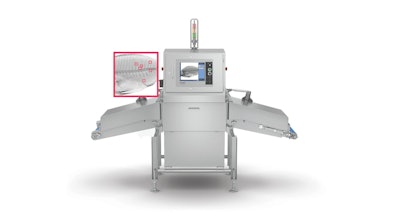

Eagle Product Inspection has unveiled its advanced x-ray systems for contaminant detection and quality assurance.

The systems are equipped with the PXT dual energy photon-counting technology and SimulTask PRO image analysis software that enable detection of bone pieces and foreign materials across a wide range of fresh, frozen and shelf-stable seafood products. The hygienically constructed equipment is designed for often-harsh environments including seafood processing facilities.

Featuring a curtain-less design for product handling, the RMI 400 can find and reject bone fragments down to .5 mm and other foreign materials such as hooks, blades, shells, sharp objects, wire, staples, metal shavings and more. The system also offers quality control checks such as fat measurement, weight verification, missing items, fill level and package integrity.

The Pack 400 HC X-ray machine is additionally designed with interlocked hinged louvers that enable fast cleaning and an easy-belt removal system. In addition to the detection of contaminants that would otherwise go unseen by the naked eye, this system can test for mass measurement, package integrity and component count.

For more information, visit eaglepi.com.