A new Tilt-Down Flexible Screw Conveyor System from Flexicon (Bethlehem, PA) is mounted on a portable base with a multi-purpose hood and an integral dust collector. This allows manual dumping from handheld sacks as well as discharging from bulk bags, subsequently transferring material to elevated downstream process equipment and storage vessels at multiple plant locations, dust free.

Discharging from bulk bags requires the user's forklift or plant hoist to suspend the bag above the dust hood, allowing the bag spout to be cinched by an iris valve, untied and then released gradually to prevent uncontrolled bursts of material from the bag.

Alternately, hand-held sacks can be rested on a fold-down support tray, slit open, and manually dumped into the hopper.

Airborne dust generated by either process is drawn away from the operator's area through the dust hood by a side-mounted BAG-VAC dust collector vented from the hood. To maintain operational efficiency, reverse-pulse air jets on a timed cycle remove accumulated dust build-up on filter surfaces, dropping it to the bottom of the dust collector for later removal and disposal.

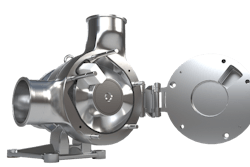

The flexible screw conveyor features an inner stainless-steel screw of specialized geometry to propel both free- and non-free-flowing bulk materials including products that pack, cake, smear, seize or fluidize, with no separation of blends.

www.flexicon.com, 888-353-9426