With the right equipment a range of products including powders, pastes, and mixtures of liquids and solids can be pumped, as well as more traditional liquid  Positive displacement pumps are commonly used for delicate products including creams, fruit fillings & purees, sauces, cheese, mayonnaise, and even meat emulsions.

Positive displacement pumps are commonly used for delicate products including creams, fruit fillings & purees, sauces, cheese, mayonnaise, and even meat emulsions.

Many types of pump are suitable for use in the food industry, including rotary lobe, rotary piston, reciprocating positive displacement, progressing cavity, peristaltic hose and air-operated double diaphragm designs. However, traditional pumps can be expensive to maintain while lobular pumps have low flow rates. In addition, using progressive cavity pumps can break the product, while double diaphragm pumps result in a low pressure drop.

The HRS BPM Series of positive displacement pumps is mounted on a mobile skid unit, making it ideal for product trials and proof of concept work

The HRS BPM Series of positive displacement pumps is mounted on a mobile skid unit, making it ideal for product trials and proof of concept work

Positive displacement pumps have an expanding cavity on the suction side of the pump and a decreasing cavity on the discharge side. Liquid flows into the pump as the cavity on the suction side expands and is forced out of the discharge side as the cavity collapses. The BP Series features a hygienic design that incorporates a separator fitted between the piston and the hydraulic chamber to ensure that there is no contact between the product chamber and the hydraulic oil, ensuring no oil comes into contact with the product.

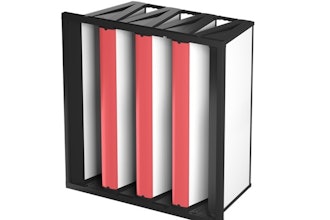

With an adjustable flow, which can range from a minimum of 80 gallons/hour to a maximum of 5,280 gallons/hour, and features a high-pressure drop of up to 435 psi, it is suitable for a wide range of high viscosity fluids that are shear sensitive  Full size HRS BP Series piston pump.

Full size HRS BP Series piston pump.

In order to allow food manufacturers to see the benefits for themselves, we created the HRS BPM Series. The BPM is a mobile version of our standard BP Series pump but is mounted on a mobile skid unit for easy movement, allowing it to be used across multiple production lines and locations. This makes it popular with food manufacturers producing short runs of specialist products and numerous trials, as they can enjoy the benefits of a BP Series pump without the need to invest in a dedicated pump for each line, resulting in considerable capital savings.