The Silvestri family has been in the renewable energy business for 14 years. Their family-owned and operated business in Ontario, Canada —SILTRI Bio Fuels Inc. — has spent the last decade and a half contributing to the global renewable energy market by aiding in the conversion of recycled vegetable oil into environmentally-friendly Biodiesel fuels.

A large component of SILTRI’s on-the-ground operation involves the refinement process, where the oil is filtered for contaminants before being shipped to the Biodiesel plant. As Joe Silvestri, the owner of SILTRI, explained, “We bring in used cooking oil from restaurants and food manufacturing facilities, filter out the unwanted impurities and moisture, then send the refined product to Biodiesel plants in North America and overseas.”

This refinement process involves multiple stages, most of which require a consistent high level of heat. Temperature plays a critical role in this operation and is key in producing a high-quality product meeting specs.

THE PROBLEMS

Before they launched their new business, the Silvestri family knew it was important they find the right equipment to reliably provide them with the requisite heat output. For this, they looked to steam boilers. The trouble was finding the right one.

Joe Silvestri was well aware that their business, and thus livelihood, depended on the continuous operation of the boiler. If it went down, so too would their operation. He also knew that he needed a boiler that could produce consistent steam for reliable temperature modulation, and preferably, steam on-demand. And, as a company with an eye to a greener future, it was imperative that the equipment they used was energy efficient.

Clayton Industries

Clayton Industries

Even further, as per Canada’s regulations, any boiler (not classified as low water volume) exceeding 50 BHP needs to have a certified operating engineer to oversee it. Otherwise, the risk of an explosion is too great.

And SILTRI’s production was going to require more than 50 BHP. As a family-run business just starting off, adding another person to payroll was not opportune.

THE SOLUTION

It was through word of mouth that Joe was first introduced to Clayton Industries’ steam generators. An old Clayton customer was closing their doors and was selling their used E-154 BHP steam generator. Joe heard about the used unit and started comparing the Clayton steam generator to the fire tube boilers he’d been looking at.

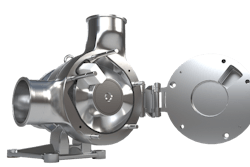

Unlike traditional boilers, Clayton’s unique counterflow design and controlled circulation system technology necessitates the use of only a small amount of water at a time. For Joe, that meant the steam generator would be able to offer more rapid start-up and follow load cycles, as well as ensure the absence of explosion hazards. And owing to these safety assurances, SILTRI wouldn’t have to invest in a stationary engineer — no matter the boiler horsepower.

As Joe stated, “it was immediately clear that the Clayton steam generator was a reliable choice.” SILTRI purchased the used Clayton steam generator, kick-starting their business in the renewable energy industry.

THE RESULTS

For 14 years, the steam generator has been a crucial player in SILTRI’s growing business. The team runs the generator non-stop whenever they are processing, which is most days. Even with continuous usage, the steam generator’s-controlled circulation design allows them to cut down on fuel and maintain relatively lower energy costs.

Moreover, as Joe stated, “set-up in the morning is easy with the steam generator, which is important for our team. To make 150 HP of steam — it’s almost instant. No lag-time at all.” Even when another tank of unheated raw material is introduced to the reactor, the generator can immediately compensate for the new load.

For Joe, an unexpected but crucial benefit of the Clayton steam generator has been its serviceability. As Joe shared, “the Clayton steam generator is the only piece of equipment I do not worry about.”

ABOUT CLAYTON INDUSTRIES

Clayton Industries is a leading global manufacturer of industrial steam boilers and industrial process steam generation products. The process steam boilers include fired boilers and unfired waste heat boilers. Clayton’s unique controlled circulation counter-flow design offers many operational advantages and benefits over other industrial steam boilers. Its control systems are built with the latest technology. Clayton also provides customers with reliable and highly efficient, compact steam-generating systems, mobile steam generators, and steam. The company’s design principles make it a favorite choice in today’s high-efficiency energy markets. Clayton Industries was established on October 20, 1930, and is headquartered in City of Industry, California, USA. It serves diverse worldwide markets from its industrial steam boiler manufacturing facilities in the United States, Belgium, and Mexico. Direct Sales and Service support centers are also located worldwide. For more information, visit www.ClaytonIndustries.com

ABOUT SILTRI

SILTRI is family owned and operated business in Hamilton, Ontario, serving local markets as well as the North Eastern United States. SILTRI was founded in 2009 as a producer of biodiesel, an environmentally friendly, renewable fuel made by converting recycled cooking oil into a green alternative fuel. The fuel reduces greenhouse gasses and can be used in all diesel engines with no modifications. For more information, visit www.siltri.com