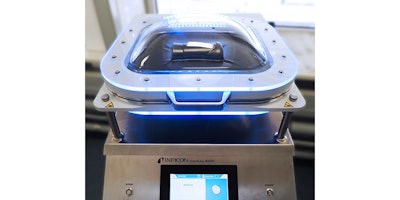

To help food manufacturers deliver products that are fresh and safe to consumers, avoid premature spoilage and prevent costly recalls and returns, INFICON is introducing the Contura S400 leak detector for Modified Atmosphere Packaging (MAP) as well as flexible packages. INFICON will showcase the Contura S400 to the North American packaging market for the first time at PACK EXPO International 2018 (October 14-17, 2018; McCormick Place, Chicago).

Already commercialized in Europe, the Contura S400 offers a faster, easier, quantifiable and more cost-effective alternative to water baths and gas-based testing. It detects both gross and fine leaks quickly and reliably, avoiding the need for two separate machines. In addition, the system does not use test gas and eliminates the damage to packaging that can often occur with other leak detection methods. The Contura S400 is ideal for a variety of dry food applications including coffee, meat, poultry, baked goods, snack foods, confectionery/candy, cheese, grains and cereals, prepared food and produce.

“Leaks in MAP and flexible packaging are typically detected in sealed seams and downgauged packaging materials,” said Bill Burnard, Vacuum Control Sales and Business Development Manager — North America. “The Contura S400 relies on a proprietary differential pressure method to identify leaks — both large and small. This unique, non-destructive approach allows dry food manufacturers to efficiently and accurately determine if hermetically sealed packages are airtight before they ever reach the market.”

INFICON (Booth E-8563) www.inficon.com