Packaged food sales are predicted to surge for the next several years reaching $3.86 trillion by 2026. To respond to both inflation and consumers' changing demands, including a desire for conveniently packaged food, ready-to-eat food, and intermediary food items, CPG companies must continue to evolve. However, many CPGs struggle with the push and pull of developing new products amidst rising prices and inflation.

To ease this tension, strategic CPG brands are exploring ways to reduce capital investment, speed time to market, and decrease overall costs. More and more, leaders at CPG brands are doing more than signing a vendor agreement with co-packers. Instead, what they are creating are strategic alliances with co-packers as a solution to this challenge. This is an entirely different approach to manufacturing than simply outsourcing packaging.

Many CPG leaders choose to work with a co-packer offering the lowest cost to meet product deadlines. There’s no denying that price matters, but there is a cost to choosing a co-packer exclusively on price – especially as inflation continues to rise.

A New Era of Contract Packaging Partnerships

Relationship between CPGs and Co-packers Shifts from Transactional to RelationalWith inflation on the rise threatening to reach 10% by the end of the year, the question is not if CPG manufacturers will increase their prices, but when and how they’ll do so. This pricing crisis comes at a time when consumer price sensitivity is also on the rise.

Delegating packaging operations to co-packers is nothing new, but today’s supply chain disruptions and soaring materials prices have raised the stakes. Any minor mishap could significantly impact a CPGs’ bottom line. As a result, the game has changed, shifting the relationship between CPGs and co-packers from transactional–where the price is the primary determinant, to relational–where picking the right partner is strategic and critical to long-term success.

CPG’s embracing this paradigm shift are not only advancing their future, but they are also investing in a strategic alliance built on trust and capability. To move forward sustainably and profitably, CPGs must invest their resources in people with the right skills and mindset to help them overcome the tremendous stress of our pandemic economy.

Here are some factors that determine contract packaging success and how to find the right contract packager:

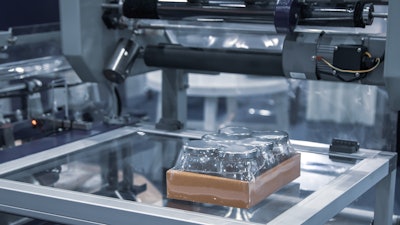

iStock

iStock

A Good Co-packer Helps Grow Your Brand and Your Product Line

Helping Navigate Challenges, Including Inflation and Supply Chain DisruptionsThe profitability dynamic has always been hard to navigate. As a result, the first stop for brands is typically to optimize their product portfolios to reduce the cost of goods.

Due to rising inflation, brands now face increased commodities, and raw materials cost as the world recovers from the pandemic. But, perhaps the most impactful dynamic is the rapid shift in buyer behavior. In terms of sheer dollar growth, buyers are moving online. As a result, CPG brands now find themselves amid an incredibly tricky profitability equation.

CPGs must find a strategic partner with the resources and expertise to meet their needs. Ideally, the co-packing partnership fit should take precedence over price. In addition, a good partner can help you navigate challenges, including inflation and supply chain disruptions.

Effective strategic alliances build trust and mutually beneficial relationships allowing brands and contract manufacturers to obtain their business objectives, such as establishing a competitive advantage, achieving an acceptable degree of supply chain transparency, and ensuring quality.

However, the reality is that most brands have transactional relationships with their co-packers, where brands would (and do) switch contract manufacturers based on who’ll manufacture the product for a lower price. Why is this?

There are several advantages a quality co-packer offers a brand. For one, the right contract packager provides an agile development process enabling brands to grow efficiently and successfully. A good co-packer helps grow your brand and your product line. They work with you to collaborate, share best practices and potential solutions. They communicate regularly and clearly to help ensure the best results, and they work behind the scenes fixing operational glitches, including quality, capability, and capacity issues. The brand, in turn, can focus on core aspects such as sales and marketing.

The problem comes when the contract packager isn't as effective as promised. Maybe your packager cuts corners on quality measures or isn’t adequately sized for the product's growing needs. Such cases create enormous liabilities for brands and can sabotage a healthy growth trajectory. If a brand must maintain constant oversight to ensure quality or divert resources to solve a co-packer’s issues, this ultimately increases the risk for the brand. It means higher levels of uncertainty in supply, which translates to higher risk and higher costs.

By aligning with contract packers, CPGs can eliminate the need to deal with packaging operations challenges and focus on their brands. A best-in-class co-packer allows CPGs to do just that.

iStock

iStock

How Much Does Waste Cost a CPG Brand?

One of the Most Significant Advantages of a Good Contract Packager is Waste ReductionAn additional reason CPGs partner with contract packagers is to keep risk out of their mainstream production systems. A good co-packer has the robust processes, mindset, and culture in place to help brands succeed. And you won’t know this if you flip right to the price page of the proposal.

One of the most significant advantages of a good contract packager is waste reduction. Here are a few examples of ways we’ve been able to reduce waste through improving efficiencies.

Through better supply chain management, products and materials arrived on time and helped improve the start-ups and changeovers, which resulted in better weekly efficiencies. As a result, this Fortune 50 brand CPG experienced higher yields and less waste. Ultimately, this saved a premiere global brand more than $100,000 in less than eight months, and the product had zero consumer complaints.

Another recent success came about as a direct result of our strategic observations. Our experienced co-packing team saw an opportunity to improve the packaging size for a toddler snack. A recommendation was presented to the CPG and then implemented. The results included a reduction of both material cost and waste, which in turn improved margins. Additionally, the improved approach to the production through data, systems and real time collaboration resulted in a reduced carbon footprint for the brand.

For CPG brands, less waste means more yield and more value for the customer. Ultimately, the goal of any good contract packager is to make its clients’ lives easier by allowing them the freedom to focus on sales and marketing. However, the right partner goes beyond this and can positively impact your bottom line.

Criteria Trumps Price for CPGs

Finding Co-packers Willing to Invest Time, Capital, and Production Capacity to Take Your Brand to the Next LevelThe advantages of relational partnerships reach beyond cost savings. CPG brands are the impetus behind the creation, and the co-packer is the force that brings it to life. In the right partnership, you can write parameters and still leave room for flexibility.

Giving co-packers some wiggle room can be beneficial, but it can also impact your final product. As a brand, you must stipulate your must-haves before giving your co-packer creative license to explore new efficiencies.

David Gray

David Gray

David Gray is CEO of GreenSeed Contract Packaging, a professional contract manufacture that manages the operational side of packaging for large and middle market multinational CPG and brands passionate about natural and healthy foods.