It's almost impossible to imagine a world without the benefits of packaging. Packaging provides product protection, safety, enhanced usability, aesthetic appeal, and optimal design, to name a few. However, packaging is often single-use. This is why packaging waste is one of the biggest environmental problems the world faces today.

Contract Packaging/External Manufacturing – The Future is Circular

One big challenge is that large amounts of packaging waste escape formal waste collection processes and waste recycling systems. Plastic and other packaging weigh in at 30% of the U.S.'s annual waste, with only 9% being recycled. The problem is complicated by the fact that China banned wasted imports in 2018. In the article "The Problem with Packaging Waste: How Zero-Waste Grocers and Powering Solutions" published by the Environmental and Energy Study Institute, the fallout from the ban is summed up: "Now, China's recyclable plastics imports are down 99 percent, leaving the United States struggling to manage its massive amounts of plastic waste with a recycling infrastructure that cannot keep up."

iStock

iStock

Contrary to our existing system, a circular economy is regenerative by design. In a circular economy, products are re-imagined to minimize waste and keep resources locked in a loop of continuous restoration. One product's end is the beginning of another's life cycle.

So, how does a contract packaging business fit into the circular economy? Let's level set what the term means first. Contract packaging, or external manufacturing, is when one company works or partners with another who manages the operations, from sourcing, producing products and packaging and assembling products into a final retail-ready package. Contract packaging is an excellent marriage between efficiency and effectiveness for CPGs looking to bypass large capital expenditures and focus on innovation, sustainable practices, customer experience and speed-to-market. Supply chain efficiencies lead to material and structural improvements like cost reduction, waste minimization, and optimizing production cycles.

Contract Packaging as a Strategic Business Decision

Evolving consumer demands, particularly with sustainability, have recently made contract packaging a strategic business decision. To stay on the cutting edge, food manufacturers are leaning heavily on contract packagers in the supply chain as they become a collaborative partner in developing sustainable packaging solutions and testing them on the line.

With increasing public demand for green packaging solutions, we see tremendous growth in the contract packaging market. In 2018, the market was valued at $45 billion and is expected to reach $103 billion by 2024.

Although it took a backseat last year, consumer demand for sustainability and increasing manufacturers' demand for economical packaging as more eco-friendly package designs return to the forefront. One united effort, the New Plastics Economy Global Commitment Foundation, led by the Ellen MacArthur Foundation and the UN Environment Program, shows how top CPGs like PepsiCo, Nestle, and Danone can do together to further a plastics circular economy.

Here are three ways contract packaging contributes to a circular economy.

iStock

iStock

Experienced contract packagers save resources in two main ways. First, they have the production facilities, expertise, and material to handle large and small packaging requirements. They use lean manufacturing techniques to minimize waste, translating into more cost savings and a reduced carbon footprint.

Secondly, outsourcing packaging means manufacturers don't have to invest in production facilities, materials and packaging equipment. This keeps overhead low, leading to a higher return on investment. According to ResearchAndMarkets.com, operational costs can be reduced by 7% to 9% from "reduced maintenance costs of machines and labor costs."

2. Industry Trends

Contract packaging conserves resources by producing economical packaging solutions that efficiently utilize finite resources, shelf space and time. Their close working relationships with packaging producers help facilitate research and development that advance the process of bringing better materials to market.

Over the last few decades, consumer behavior moved packaging materials away from paper and cardboard in favor of plastic. However, in retrospect, paper is emerging as the most eco-friendly option.

3. Intentional Sustainability

Currently, the widespread use of single-use packaging is an environmental burden. Packaging waste management faces one major challenge. Existing recycling systems cannot handle the amounts of packaging produced. The demand for single-use packaging has outpaced global growth rates, and waste collection and recycling systems cannot keep up.

Sustainable packaging is fit-for-purpose and achieves its functionalities while saving on resources and reducing its carbon footprint. Design and production need to be effective, efficient, and circular to achieve sustainability in the packaging industry.

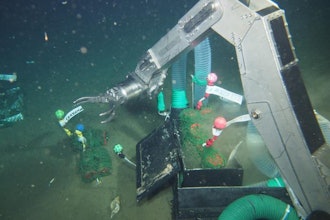

Plastic pollution carries a hefty price tag. Every year, 8 million metric tons of plastic lands in the world's oceans, costing billions of dollars in damaged and lost resources. According to a study published in the Marine Pollution Bulletin, plastic waste in the oceans costs up to $33,000 per tonne in reduced marine ecosystem value, resulting in up to $2.5 trillion in losses a year. A circular economy for plastic where continuous regeneration prevents it from becoming waste is the goal.

In response to consumer demands and regulatory requirements, manufacturers need to adopt sustainable packaging best practices and rethink delivery chains. By doing so now, companies will also position themselves more competitively.

Is Your Brand Leading the Way in the Circular Economy?

Business sustainability has come a long way. Less than a decade ago, going green was relatively novel and something only forward-thinking companies would do. Nowadays, sustainability in business is not only the norm; it is also expected.

At the heart of the packaging waste problem is the linear industrial model that emphasizes a make-use-dispose consumption model. Transitioning to a circular  Gray

Gray

David Gray is CEO of GreenSeed Contract Packaging, which manages packaging operations for large and middle-market CPG manufacturers passionate about natural and healthy foods.