The old adage that oil and water don’t mix isn’t entirely accurate. While it’s true that the two compounds don’t naturally combine, turning them into one final product can be done. You just need an emulsifier, an ingredient commonly used in the food industry.

Yangchao Luo, an associate professor in UConn's College of Agriculture, Health and Natural Resources, is using an innovative emulsification process for the development of a healthier shelf-stable fat for food manufacturing.

Luo is working with something known as high internal phase Pickering emulsions (HIPEs). High internal phase means the mixture is at least 75% oil. Pickering emulsions are those that are stabilized by solid particles.

Previous research in Pickering emulsions has focused on non-edible particles, but Luo is interested in bringing HIPEs to the food industry as an alternative to trans and saturated fats.

This new approach could have a major impact on how food is produced and could make it easier for food manufacturers to include healthier fats.

Many processed foods are loaded with saturated and trans fats for flavor and to extend a product’s shelf life. Consuming these fats can increase the risk of cardiovascular disease, type 2 diabetes, and LDL cholesterol.

Not all fats are bad though. We need fat in our diet to support normal cellular function and healthy alternatives, like olive, avocado, and sunflower oils, do exist.

Saturated fat and trans fat are solid at room temperature, meaning a suitable replacement would also need to be a solid. Healthy oils are liquid at room temperature. Luo is addressing this challenge by using edible nanoparticles to transform these oils into gels.

Luo has been working on combining healthy oils, like sunflower, soybean, or avocado oil with water and nanoparticles to create edible HIPEs. The nanoparticles Luo uses to create this emulsion come from food sources like egg yolks, soy protein, and milk protein. Once the oil is stabilized, it becomes a gel-like block.

“The cool thing is we have food-grade, edible nanoparticles in this system,” says Luo, who is a member of the Department of Nutritional Sciences. “We are trying to extract and purify those nanoparticles from the food and then reuse them in this type of emulsion structure so they can provide maximized nutrition benefits and also food quality to the consumers.”

The nanoparticles Luo works with need to be extractable from the food source without using inedible chemical solvents. They also need to be digestible and have a very uniform structure. The latter is critical to ensuring they will coat the oil molecules completely so the gel can form, otherwise it may be too liquid to mimic the texture of saturated and trans fats.

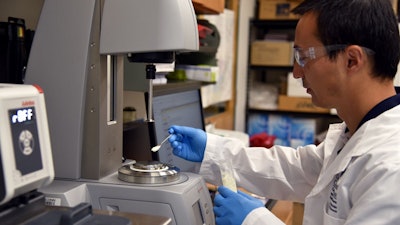

Luo is testing the emulsions for flowability, or how liquid versus solid they are. Luo is currently working on striking the right balance between oil and the stabilizing nanoparticles.

“If you have too much oil there, the gel may be very rigid and hard for chewing,” Luo says. “But if there’s too little, it may be quite flowable, so it doesn’t mimic the solid fat texture.”

In a recent study, published in Food Hydrocolloids, Luo determined the optimal cooking temperature and pH for these emulsions.

The ideal cooking temperature, Luo found, is 80 degrees Celsius, which is the temperature food products are often exposed to during pasteurization. The ideal pH is slightly acidic, between 4 and 5.

One of the challenges Luo is combatting is that unlike saturated and trans fats, the oils he is working with are subject to oxidation. Adding natural antioxidants like vitamin E and C to the emulsion helps counteract this.

One of the most important considerations for making HIPEs an attractive option for the food industry is ensuring the products it is used in will have a long shelf life, including being able to be frozen and thawed. Additionally, many food products use a lot of sodium, which can destabilize an emulsion.

Overcoming these challenges is the next step in developing HIPEs as a viable alternative for the food industry.

In addition to the inherent health benefits of replacing trans and saturated fats with healthier options, Luo says researchers can also add nutrients to HIPEs.

Luo is working with faculty in the School of Engineering to 3D print HIPEs to create a stand-alone food product packed with essential nutrients. This could be a great boon for those who have a hard time swallowing, like young children or the elderly.

This development could also have applications for precision nutrition, since both the water and oil contents are easily tunable to fortify water-soluble and fat-soluble nutrients in a single food product.

“We’re hoping in the near future we can really make this by 3D printing and putting different nutrients together so we can personalize this product for different populations,” Luo says.