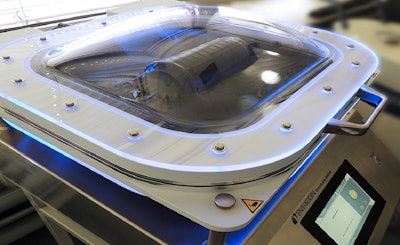

INFICON (Syracuse, NY) recently unveiled their Contura S400 leak detector with features that include:

- A non-destructive testing approach that the company feels is more reliable than water bath testing.

- Designed for food applications that include coffee, meat and poultry, baked goods, snack foods, confectionery/candy, cheese, grains and cereals, prepared food and produce that are contained in Modified Atmosphere Packaging (MAP) and flexible packaging.

- Works by placing the package between two unique membranes that create a conformal vacuum chamber that is quickly evacuated. Air flows through any package leaks and into the chamber where it causes an increase in pressure.

- A patented high precision vacuum gauge measures this change to calculate the package’s leak rate, delivering results in seconds.

- The ability to detect micro and gross leaks, eliminating risks from a package with a tear or a non-welded sealed seam that might be incorrectly identified as airtight.

- Works independent of gas.

- A stainless steel housing and dirt-resistant protective cap.