Packaging juice in pouches precisely and quickly is a difficult task. Juices with high water content pose a significant risk of splashing during the filling and sealing process, while their high sugar content can cause stickiness, leading to machine cleanliness issues. These disruptions can compromise packaging operations and seal integrity. Manufacturers require strategic solutions to mitigate these challenges.

A global juice co-manufacturing company recently partnered with Waldner North America (WNA) to install an efficient, reliable machine to enhance their juice filling and sealing process and optimize speeds.

“Our machines can produce up to 480 pouches per minute. These industry-leading numbers make our machines the fastest available on the market for high-capacity, premade pouches,” explained Matthew Boghdady, customer success manager at WNA.

Guaranteed efficiency and reliability

The juice co-manufacturer collaborated with WNA, utilizing Waldner’s premier filling and sealing machines to manufacture both pulp-free juice and frozen juice slush in pouches. The juice company now achieves up to 99.78% OEE (Overall Equipment Effectiveness).

“We helped our partner reach the highest efficiency levels and speeds possible, all while educating their operators about the technology and its processes. We’ve also established a strong business relationship and clear communication with this manufacturer, and they now are a reference for our machines,” said Matthew Gwin, product manager at WNA.

The advantages of WNA’s machinery start even before the filling and sealing process begins. The machines are equipped to automatically save time, labor and space on the infeed – where pouches are loaded before filling.

“Most manufacturers have to lay their pouches on an infeed conveyor and manually shingle the pouches to create proper spacing between them. This process is time consuming, and the pouches may not be aligned properly, leading to mishandling in the machine. WNA machines eliminate this need. We’re able to stack them in a magazine, saving operators a ton of labor and time,” Gwin added.

In addition, Waldner implements a “no pouch, no fill” rule using individual lane control. Sensors strategically placed throughout the machine verify the presence and proper opening of each pouch to receive the food product. Any pouches that fail to meet the standard criteria are automatically rejected during the filling and sealing process, ensuring uninterrupted operations.

Gwin explains that without this feature, manufacturers will either waste the product by filling it into a trough or halt operations to manually resolve the issue.

“While it may not seem significant, these outdated processes can quickly become extremely wasteful and tedious,” he said.

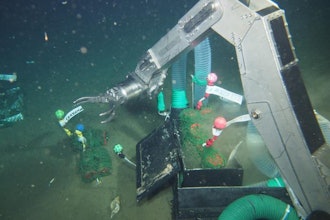

Waldner’s advanced filling and sealing machines.Waldner

Waldner’s advanced filling and sealing machines.Waldner

Innovative filling and sealing process

Preventing juice overflow during the filling and sealing process is also a significant challenge. Boghdady explains that Waldner’s flexible machines are constructed to guarantee no splashing occurs outside the pouch or onto the sealing area. During the filling process, Waldner machines can either lower the product nozzle to the container or lift the container to the nozzle. By minimizing the distance between the nozzle and the pouch bottom, the product drops from a lower height, reducing velocity and splashing.

Once the product is accurately filled, it proceeds to the sealing process. Waldner offers two types of sealing: heat sealing and ultrasonic sealing.

Boghdady explains that heat sealing is more common and slightly less complex than ultrasonic sealing. However, ultrasonic sealing is impressive for its ability to seal through liquids, even with splashes in the seal area, and solids alike. WNA partners with global technology leader Hermann Ultrasonics to conduct the ultrasonic sealing process. This collaboration enables real-time feedback from the ultrasonic system, notifying the Waldner machine of any improperly sealed pouches and automatically rejecting them.

“Our customer selected a unique approach by using both heat and ultrasonic sealing processes. This achieved optimal results, as the ultrasonic sealing effectively cut through liquids and solids to create a hermetic seal, while the heat sealing provided a clean cosmetic seal across a larger area, ensuring complete closure of the top of the pouch,” he concluded.