As profit margins grow tighter, manufacturers continue to seek new solutions to ensure freshness and product integrity while reducing waste. Certainly operational improvements and inventory management play a major role in profitability. But manufacturers that partner with label and packaging converters are discovering new ways of increasing their margins and maintaining quality throughout their supply chain.

For example, technologies such as flexible packaging have evolved to deliver significant value to food manufacturers. Flexible packaging provides the necessary barrier to help keep food fresh on the shelves for longer periods of time while delivering outstanding brand recognition and requiring less material than traditional packaging. That translates to less waste and enhanced marketability. And flexible packaging continues to become the packaging of choice, thanks in part to a reclosure option that outperforms zippers, sliders and pressure-sensitive seals.

What’s on the horizon? Think “flexible packaging in a smaller size — stick packs — that can lead to bigger profits.” And think “smart labels that can save my bacon — literally.”

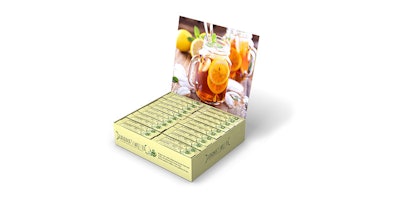

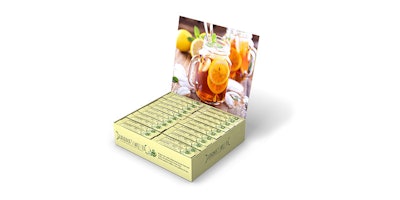

Small Means Big

Smaller packages can provide the potential for bigger sales and profits. Stick pack packaging — the single-serve variety that can be used for a wide variety of food and beverage products such as candy and other sweets, liquid flavorings, breakfast drinks, coffee/tea and condiments — is growing exponentially. According to a report by Freedonia Group, stick packaging is projected to grow at a rate of 5.6 percent through 2018, significantly outpacing the tube packaging it often replaces.

Stick packs are upscale and a viable consideration for brand expansion into the single-use and bundle packaging markets. Short runs for promotional packaging or regional products are easily attained. There’s also the opportunity for 360-degree packaging decoration.

Advancements in this packaging such as no-notch stick packs ensures an easy-open experience for consumers and helps eliminate the potential for a misplaced notch that doesn’t work properly — and can lead to wastes and returns. While easy-open packaging carries a slightly higher cost, it’s a sure way to help avoid variables and scrap.

Stick pack products provide 10-40 percent less packaging than traditional packaging, and they take up less space in shipping, on shelves and racks. They also reduce a manufacturer’s carbon footprint because the packaging emits less carbon dioxide. An even more sustainable option is available with new, responsibly sourced bio-based material. This cellulose-based material features a lamination combined with a Surlyn sealant to provide a clean, no-notch opening.

Single-use packaging is a great option for today’s grab-and-go lifestyle. Manufacturers currently using — or considering expanding into — single-serve portions can benefit from learning more about all of the stick pack options available today.

Photo courtesy of Avery Dennision

Photo courtesy of Avery DennisionTime and Temperature, Courtesy of … a Label

Manufacturers of temperature-sensitive products, along with their customers, are acutely aware of what exposure to temperature spikes in storage or shipping can mean. It’s the “land of the lost” — lost resources, lost time and lost profits. At times, it likely leads to a lost customer.

Traditionally, time and temperature data for refrigerated and frozen products has been recorded by data loggers. The data loggers are affixed to individual pallets prior to shipping. They record time and temperature events throughout the warehousing and shipping cycle. Upon receipt of shipment, logistics personnel download the recorded data by plugging the data loggers into a computer to determine if the product has been shipped safely within temperature parameters. The data loggers must be shipped back for re-use — an added cost. Often, data loggers are lost or broken during the return process — another potential expense.

But a new technology brings credit card-sized labels and smart phone technology to the rescue. Utilizing a label that includes near field communications (NFC) technology and a time- and temperature-sensing microchip, each box on a pallet can tell the history of its journey through the supply chain. The label can be affixed to or placed inside each container.

Photo courtesy of Avery Dennison

Photo courtesy of Avery DennisonRead by placing an Android smartphone that uses a specially designed app against the label, the label’s recorded data tells whether a product shipment is suitable for sale and consumption before it is even off the truck. The data can be sent to cloud storage for proof and/or analysis, or for FDA recording requirements — and there’s no need to plug the phone into a laptop to do so. It can all take place from point-of-delivery.

The user defines the temperature recording intervals, depending on the temperature sensitivity of the product. For example, a shipment of lobster tails may require more frequent recording intervals than a shipment of frozen vegetables. The intervals can be set within seconds, minutes, hours or days. Temperature accuracy is within +/- 0.5 degrees C.

Each disposable label employs a flexible battery in addition to the NFC chip, and can offer a savings approaching 50 percent over the use of bulky data loggers. Most importantly, however, the technology offers a sustainable solution that offers the ability to reduce waste and shrinkage while maximizing profitability for all parties involved.

Partnerships Can Mean Profitability

With profitability at razor-thin levels, reaching out to supply chain partners can make all the difference for food manufacturers. Converters and packaging experts and shipping and logistics professionals provide often-untapped resources that can deliver big benefits. Working closely with these partners, and keeping abreast of the latest developments in label and packaging technology is a formula that will pay off today and in the years to come.