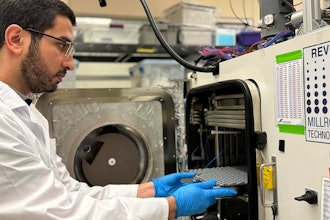

The 745 multi-outlet forming machine combines accurate weight control and quick changeovers with mobility. A vane pump feed system uses a rotating spiral to gently move product to the rotor, eliminating overworking, bridging and backflow. The vane pump feeds directly to the mold plate cavity and can portion up to 11,700 patties per hour. Processors can portion beef, pork, poultry, fish, veal, lamb, cheese and vegetables. Mold plates can be changed in less than five minutes. The machine can be sanitized minutes after production is completed and can easily be transported to a washdown area. Larger parts can stay on the machine and easily swing out of the way for fast cleanup.

Forming Machine

The 745 multi-outlet forming machine combines accurate weight control and quick changeovers with mobility. A vane pump feed system uses a rotating spiral to gently move product to the rotor, eliminating overworking, bridging and backflow. The vane pump feeds directly to the mold plate cavity and can portion up to 11,700 patties per hour.

Dec 14, 2011

Latest in Capital Investment