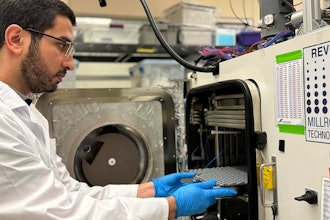

The new C3572 checkweigher features production monitoring and control features to help optimize the checkweighing process and increase production efficiencies. Higher production rates, better accuracy, and less downtime improve overall system performance and lead to increased OEE. The C3000 frame meets the safety needs of high volume food processors by incorporating sturdy stainless steel conveyors with an open and accessible frame design. Elements of applicable standards from AMI, USDA, 3-A, SQF and other key food safety organizations were applied in the design and construction of the C3572 to ensure the highest level of food product safety. Ideally suited for food production areas with heavy washdown requirements, the C3572 checkweigher’s modular design ensures a system that meets the highest standards for food safety in the production environment. A complete library of package handling, functional and operational, production monitoring and control, and communication options allow for a custom-tailored solution to meet any application. Complete line integration and PackML (ISA-88.00.02-2008) communication capabilities support the user’s continuous improvement and OEE program.

Mettler Toledo