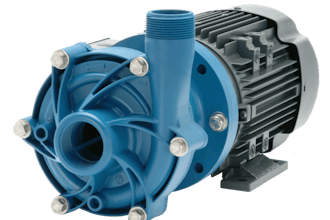

Custom mixing systems from INDCO (New Albany, IN) are engineered to optimize unique processing projects including batch size, material properties, agitation levels and more to achieve desired process results. Working closely with customers to fully understand industry requirements as well as operational and site-specific constraints, INDCO engineers can develop a mixing system including mixers and tanks from simple open-top designs to full ASME jacketed vessels. Whether temperature is controlled to ensure viscosity of materials, to utilize heat as a catalyst, or for other reasons, jacketed tanks are often a crucial element of custom mixing system designs.

INDCO engineers can provide a fully integrated mixing tank and mixer design including tank jackets and a host of other features including polished and electropolished surfaces, dip tubes and drain valve designs, and more. All INDCO products are made in the USA with industry leading warranties and lead-times.

www.INDCO.com, 800-851-1049