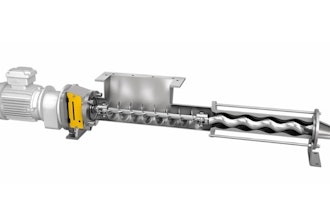

ROSS (Hauppauge, NY) Ribbon Blenders, known for exceptional quality and long-term performance, handle a wide range of dry materials, from seasonings and beverage mixes to pharmaceuticals, chemicals, plastics and agricultural powders or granules. These blenders also efficiently incorporate minor liquid components to effectively coat individual solid particles. Specifically:

- The ROSS Model 42N-18SS is crafted from type 316 stainless steel with interior surfaces polished to a 150-grit finish for easy cleaning.

- With a maximum working capacity of 18 cu.ft., the pictured blender is direct driven by a 10 HP gearmotor for processing materials with a bulk density of up to 60 lbs/cu.ft.

- The agitator is a solid double ribbon design, ideal for center discharge, with internal flanges welded to shaft stub ends and a heavy-duty anti-friction bearing on the non-driven end.

- A two-piece safety grating with ½" diameter perforations ensure safe operation while the split folding covers are open.

- A spray bar with fan type spray nozzles is installed on the trough via sanitary tri-clamp connections for liquid additions.

- The blender is operated from a 4” color touchscreen that includes a cycle timer, start/stop, forward/reverse and speed controls.

- The finished product is discharged through a pneumatically-operated 4″ dust-tight knife gate valve.

www.mixers.com, 800-243-ROSS