Mission Produce, named after the 21 Spanish missions built up and down California from 1769 to 1833, is a 30- year-old processor and packer of avocados and asparagus with distribution centers throughout the U.S., Mexico, Canada and the European Union. From its primary operations in Oxnard, Calif., Mission draws avocados from farmers across Southern California.

“Mission Produce is a pioneer in chilling avocados,” said Nicholas Llanos, Mission Produce Engineering Project Manager. “We do our best to maintain cold temperatures on the avocados, but this chilling is part of what created the issue Sonic Air Systems helped to resolve.” Since 1990, Sonic has designed and manufactured high velocity air blowers and air knives for myriad uses. Avocados, however, offered uncharted territory.

The chilling process begins when shipped avocados are rolled into a hydro-cooler, where they are rinsed for 45 minutes in 38˚F water. The precise climate control of each warehouse keeps the fruit in perfect suspension, without any aging or ripening, until each harvest is called up to the packaging building to be washed, graded, labeled and boxed. At that point, Llanos and his team encountered a major problem: water condensation.

“Because we do cold storage, as soon as we take those bins out of coolers to the open-air environment of our packing house, you get water condensing on the fruit. They hit Southern California ambient air temperature which is not near 38˚F. This makes it terribly challenging to put stickers on. Also, avocados are not as smooth as apples or oranges. We face a unique challenge with our labels. That drove us to look for a solution.”

Loose stickers were a nightmare at Mission. “They caused a lot of wasted time and labor removing labels from our machinery. Once the avocados are labeled, they are transported in little cups where the stickers could either just come off due to wind or rolling around. They would adhere to the belt, cup or other machinery. On a daily basis we had a cleaning procedure we went through as we tried to alleviate this mess we’d created,” Llanos said.

Poor sticker adherence was a potential threat to Mission’s organic business, which comprises 10 percent of its avocado output. “Organic regulations are tight, especially for our European and Japanese customers, and we had a huge concern that an organic label would fall off and work its way onto a non-organic piece. We could get fined for that. There was the potential for losing business.”

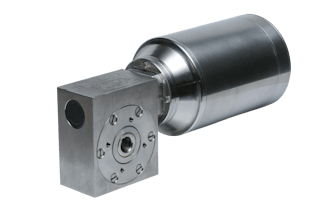

Sticker adherence was the first project Llanos, a recent mechanical engineering graduate from Loyola Marymount University, was assigned. “By installing a Sonic Air Systems high velocity air knife and air blowers, Mission Produce was able to convert a 40-45 percent adhesion rate to almost double, in the 80s,” said Llanos.

That’s amazing success, spurred by the free rein Llanos was given to search out best solutions. “Mission Produce is in a state of change, where you have a lot of old processes and habits and things going that way for 20 years,” noted Llanos. “Trying to make a u-turn takes a little while, but you have people here willing to say ‘turn the wheel, give it a go.’”

Llanos first explored compressed air knives and after his analysis, found that “the amount of air we would have to use was totally ridiculous. That actually almost put the project on hold. Then, I was digging through a food engineering magazine and saw an ad for a Sonic air blower.”

The Sonic team and Llanos determined the best solution: eight air knives in a row, allowing a blast of air on the avocado 24 inches (or one-half second) before the labeler.

The Sonic equipment has been in operation since March 2013. “It needed only slight adjustments. We had to align the air knives with the track and figure out how much air pressure to use. A Variable Frequency Drive (VFD) helps us with that. We can turn the pressure up or down; if we have it too high with smaller avocados, we can shoot them right out of the cup.”

In addition to almost doubling adhesion rates, the Sonic installation resulted in less downtime for label clean up. “We were able to cut down our label-removal cost by about 15 percent, which equates to 270 hours over the 40 week season,” noted Llanos.

Also, noise levels in the work area were significantly reduced. “A sound enclosure on the blower really lowers the volume,” said Llanos. With the previous system, the area had been tagged by OSHA as too loud to station a full-time worker. “Now we can have someone there fulltime.”

Another plus, for Llanos’ engineering eye, is the Sonic presentation. “It’s compact, you can fit it into many places. It’s an extremely high-grade product with chrome-plated aluminum air knives, very well engineered. As far as the blower goes, it’s plug and play. The thorough design appeals to me as an engineer and has really proven itself well in our environment.”

Mission Produce also operates a second Sonic system comprised of a single air knife at the fruit wash. “It blows water back into the wash unit to eliminate water reaching the rest of the equipment and possibly causing corrosion and rust,” said Llanos. He reported more Sonic systems will follow at Mission Produce’s new facility just down the road, where the plant will soon move. “Sonic has huge potential as far as where they can take their technology. Large and small. I could come up with a million applications for these things.”

First in line: avocados.